METAL 3D printing

4차 산업혁명의 미래를 주도하는 미래인입니다.

Metal 3D printing

(PBF method)

DAVID metal 3D printer developed by Merain

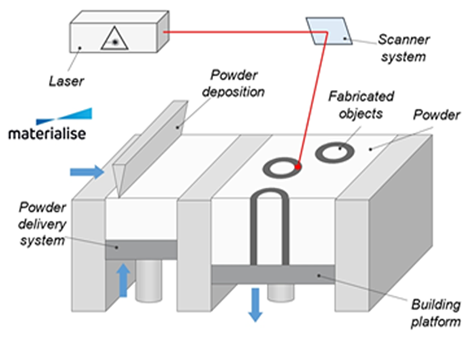

is an SLM metal 3D printer using a PBF method. PBF(Powder Bed Fusion) is a layered manufacturing method

repeating the process of using a laser to irradiate path

data corresponding to each layer through a process called slicing

based on process variables from 3D data, then thinly applying

small metal powder with a spherical shape between the size

of 15um~45um on the bed for each layer, then melting it again with

a laser as if drawing a picture, and then applying metal powder again.

is an SLM metal 3D printer using a PBF method. PBF(Powder Bed Fusion) is a layered manufacturing method

repeating the process of using a laser to irradiate path

data corresponding to each layer through a process called slicing

based on process variables from 3D data, then thinly applying

small metal powder with a spherical shape between the size

of 15um~45um on the bed for each layer, then melting it again with

a laser as if drawing a picture, and then applying metal powder again.

Introducing laser method

The laser used in metal 3D printers is a structure that moves the electron beam

by controlling the laser’s hatching path using a galvanometer mirror scanner.

by controlling the laser’s hatching path using a galvanometer mirror scanner.

# Implementing complex shapes

# Decrease in manufacture process

# Manufacture of high value metal parts

As its strength, it has the best precision among Metal AM and is the most used method

for manufacturing precise parts in metal 3D printing. As its disadvantage, it is not easy to mass produce metal powder so a high price is formed,

and most 3D printers are expensive due to their laser system. Merain is researching and developing metal 3D printers on its own, and has acquired localization

of Co-Cr metal powder and GMP grade 2 certification.

for manufacturing precise parts in metal 3D printing. As its disadvantage, it is not easy to mass produce metal powder so a high price is formed,

and most 3D printers are expensive due to their laser system. Merain is researching and developing metal 3D printers on its own, and has acquired localization

of Co-Cr metal powder and GMP grade 2 certification.

3D VIDEO